Description

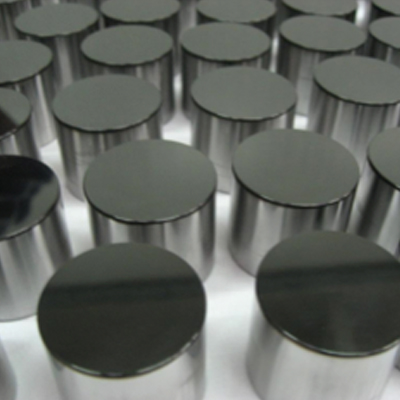

CERTESS®CARBON DCX is a dense, metastable form of hydrogenated amorphous carbon (a-C:H) containing significant SP3 bonding. This process of bonding carbon and hydrogen confers valuable 'diamond-like' properties such as mechanical hardness, low friction, optical transparency and chemical inertness. CERTESS®CARBON DCX also has an amorphous hydrogenated carbon (a-C:H) layer with a standard metallic sublayer for standard application.

Federal Firearms Licensee (FFL)

Substrate(s)

- Tool Steels Maraging Steels

- Stainless Steel

- Titanium

- Alumiunium

Temp. Ratings

Thickness

- Thickness (micron): 1 - 5

Color(s)

Process

CERTESS®CARBON DCX can be applied to almost any material that is compatible with a vacuum environment and can withstand 220°C. Most widely used applications are tool steels, maraging steels, stainless steels, aluminum and titanium.

Advantages

High hardness, Excellent abrasive wear resistance, Low thermal conductivity, Ultra-Low friction level.

- Chemically Inert

- Corrosion Protection

- Extreme Low Coefficient of Friction